- Overview

- Climate change mitigation and adaptation

- GHG Management

- Air pollution management and prevention

- Water Resources and Waste Management

- Environmental Expenditures and Benefits

Energy management

We appointed dedicated personnel at business departments and factory offices to implement numerous process improvement and energy management projects, so as to continue reducing emissions.

Energy Use and Consumption

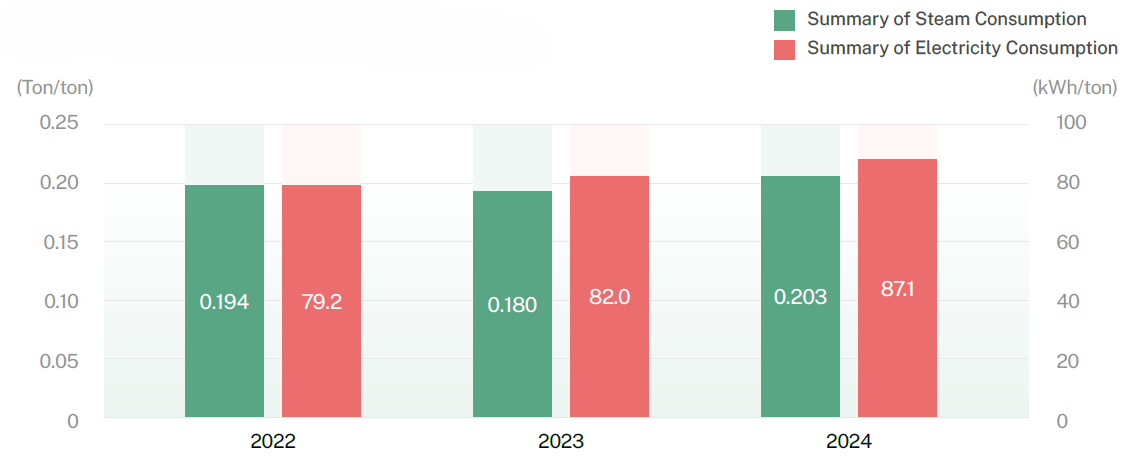

Energy Intensity per Unit Product over the Years

Note 1: Types of energy covered by the intensity ratio: fuel and electricity (including purchased electricity)

Note 1: Types of energy covered by the intensity ratio: fuel and electricity (including purchased electricity)

Note 2: The energy calculation boundary covers Scopes 1 and 2 (both are internal usage of the organization)

Note 3: Formosa Plastics Group Business Intelligence system database

In 2024, the Company’s total production capacity was 28,323 thousand tons, used 5,754,803 tons of steam, and used an average of 655 tons of steam per hour, which is the equivalent of 0.203 ton/ton per unit. The annual electricity consumption was 2,466.4 million kWh, with an average hourly electricity consumption of 280,786.8 kWh, which was equivalent to a unit electricity consumption of 87.1 kWh/ton. In 2024, the amount of steam and electricity consumed per unit product both increased compared to the previous year, mainly because of the low production achievement rate caused by the process load reduction or shutdown due to market demand. In the future, we will continue to implement various steam-saving and electricity-saving measures to reduce steam and electricity consumption per unit product.

Implementation Status of Main Energy Conservation Projects

Energy Conservation Action Plans

Summary of Historical Energy-Saving Performance

Total Energy Consumption over the Years

Note 1: Source: The Formosa Plastics Group computer-based database for environmental protection improvements

Note 2: Types of fuel: coal, fuel gas, etc. are all converted to standard coal